Machining Services

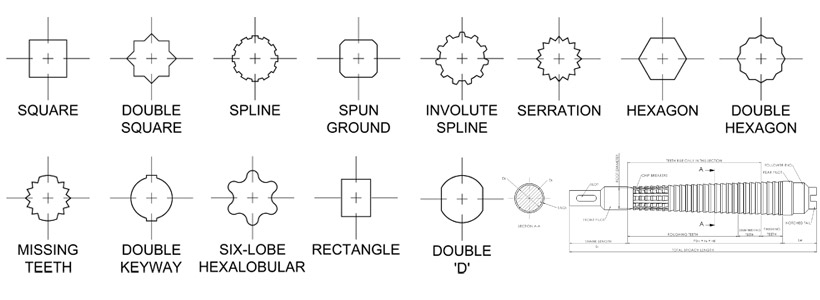

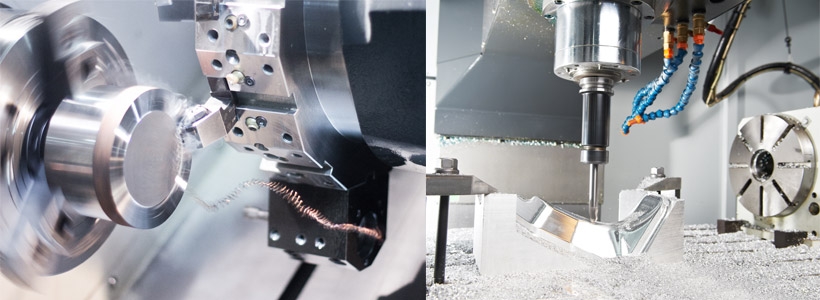

As one of North America's largest gear and spline manufacturers, Perry Technology has invested millions of dollars in advanced machinery and tooling for manufacturing any type of gear, spline or complex machined part.

We can manufacture your parts from drawing to final inspection, or we can perform individual operations such as cutting or grinding just teeth. Our wide variety of in-house capabilities, including an extensive tool making department and a variety of secondary operations, result in some of the fastest turnaround times in the industry.

In addition, our team of expert engineers and machinists have helped earn Perry Technology recognition throughout the industry for our ability to deliver precision and quality in all our complex machining, custom gear, and custom spline orders.

Whatever your requirements are, we have the equipment to fulfill them.